Use Cases

Environment sensor

Goal

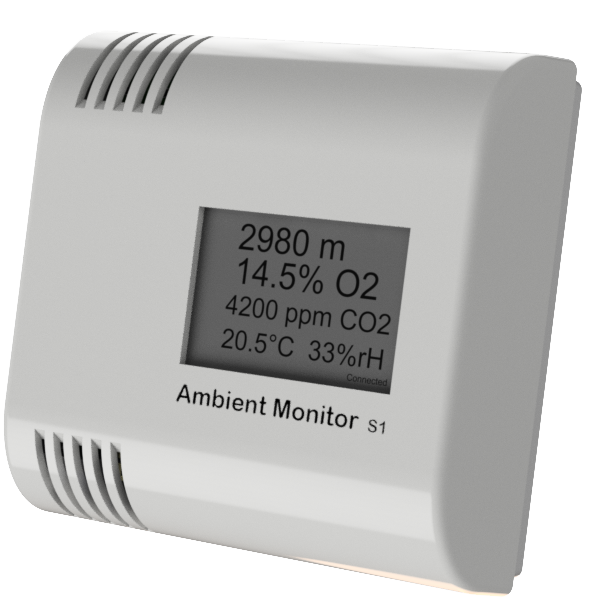

Measuring environmental variables such as oxygen and carbon dioxide levels, temperature, pressure, dew point, relative and absolute humidity. These are used to monitor rooms with artificial environment conditions (e.g. data centers, warehouses, altitude training center, etc). The values are transmitted to the controller via Modbus. In addition, sound alarms and relais can be configured on the device, to be triggered under specific conditions.

Technical specifications

- Processor: SMT32 series

- Remote control and monitoring via Modbus

- Configurable display

- Communication with sensors via RS485 and UART

Description

This sensor continuously measures O2, CO2, temperature, pressure and humidity. With these values, different variables can be calculated: Dew point, current altitude (Oxygen level based), O2 partial pressure, etc. The sampling rate of these measurements can be adjusted as needed.

Depending on these measurements, individual alarms can be set: For example, for low O2 and high CO2 levels, temperature and humidity. These alarms set off a beeper, which also triggers a relay. The alarm can be used to automate and control other buildings. The alarms trigger an alarm tone on the device and activate the alarm relay. With the values measured and transmitted to the control device and the alarm values of the device, the environmental values of the building can be checked automatically. All parameters such as alarms, relay status, the display and other settings of the environmental sensor can be configured both via an interface and via a Modbus connection (with 9600, 18400 and 39700 bauds). The devices are available with configurable IDs.

Customers use our O2Sensor to monitor the oxygen level in the training rooms, which is reduced for altitude training, as well as to monitor storage rooms and data centers and to trigger appropriate procedures in the event of an alarm.

asisVS-100

Goal

asis VS-100 is a driving data registration device, with programmable control device functions. The device must meet the necessary standards for rail and road vehicles and be approved throughout Europe.

The control functions should also be suitable for safe applications and also allow operation in mountain railways with high requirements.

Technical specifications

- 16 digital hardware inputs

- 64 digital hardware inputs via CAN/TRDP

- 8 analog inputs

- Time/date management via GPS, CANopen, TRDP, RS485, IBIS

- 4 transistor outputs and 8 relay outputs

- Safety binout output

- SIL-2 / SIL-3

- All outputs and information via CANopen/TRDP

Description

With the built-in display and the operating option directly on the device, the asis VS-100 offers efficient support during installation in the vehicle and during operation without additional devices. The CANopen and TRDP functionality allows connection to the vehicle system. Its programming functionality, which is geared towards railway vehicles, enables the implementation of safe functions such as roll-back protection, deceleration monitoring, safety switching and many other functions. The multiple recording of the data means that it is secure even if one data storage device fails. With the asisCHARTS evaluation program, the recorded data is presented according to customer-specific requirements. The asis VS-100 is 100% produced in Switzerland.

asis is a registered trademark of SYNICS.

Wellness control

Goal

A wellness control for a sauna, finarium and steam bath, controlled with both a physical interface and an intuitive smartphone app. The hardware, server software and client software was developed by SYNICS, as well as the hosting of the server system.

Technical specifications

- Progressive web app to manage saunas also in smartphones and PC

- Client-server architecture

- Interface for managing users and querying the status of the system

- Support and service by SYNICS

- CAN bus to manage the sauna locally from the physical interface

Description

A web app allows the user to operate the wellness facility. This is done via a SYNICS-owned service. The system automatically connects to the Internet and executes the requests of the service. Integration into the local network is possible both with cable and in the protected WLAN, as dynamic IP addresses are managed. SYNICS supports the system builder in user administration and maintenance of the sauna software.

The recorded data enables the plant manufacturer to query the plant status remotely in the event of service requests from the plant user and to process the service more efficiently. Service planning is optimized through the possibility of preventive maintenance.

The wellness facility can be controlled both via a local control unit, with the web app and over modbus.

The control has an intelligent three-phase control. This guarantees a long service life of the power elements and detects phase failures. The control power of 12kW can be extended up to 20kW.

Wind measurement device for tunnels

Goal

Monitoring the wind speed in tunnels requires reliable measuring probes. The aggressive air caused by exhaust gases massively reduces the service life of the bearings of probes with moving parts. A probe without moving parts was developed.

Technical specifications

Measurement using ultrasound for two different wind directions

- Arm7 microcontroller

- RS-485 communication

- Profibus connection

- Robust construction

Description

Wind speed measurement in a tunnel is primarily used to control the ventilation fans in the event of a fire. Mechanical devices such as anemometers require frequent maintenance to function in these environments. Thanks to the structure of the APT TK-300, the maintenance effort is greatly reduced.

The probe measures wind speed by measuring the time difference between the phase shift of sound traveling through the air moving. The transit time difference is very small, requiring complex mechanisms to achieve the required measuring accuracy, such as phase shift and synchronous demodulation techniques.